Fuel System

Image Gallery

Research

Fuel Filters

- North Carolina Ferry System has … engines are fitted with Racor diesel filters with water separators and the normal fuel filters that are supplied by the engine manufacturer just like most recreational trawlers. Water separators are tended everyday. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- important that fuel filters be installed in the line in an accessible location, along with water/particle separators. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 241)

- So you can monitor the filter’s efficiency, it’s a good idea to rig a pressure differential gauge or a vacuum gauge between the fuel filter and the engine. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 241)

- Fuel filters should be so laid out that they are also readily available and accessible (From a Bare Hull, p. 154)

- Once your fuel lines are hooked up, fill your tank with a couple of gallons of fuel (just in case they leak diesel). Bleed the system starting from the top most filter and working your way down to the injectors. Th operation is simple. Loosen the bleeding screw until fuel starts flowing instead of air, then tighten it and go on to the next one. But be sure you tighten one before you ascend to the other, or you’ll be wasting time, for the bottom one will be letting air in. (From a Bare Hull, p. 321)

- …diesel engine’s fuel system[s] are machined to incredibly precise and minuscule clearances that simply to not tolerate contaminants…prevention – keeping contaminants out of the fuel – is better than a cure – removing contaminants from the fuel. (Cruising Handbook, p. 206)

- A variety of screened funnels on the market (Baja funnels are the best known) can be used to take out the worst sediments when refueling, but it often difficult to throttle down the flow from the fuel pump to the rate at which the fuel moves through the funnel (Cruising Handbook, p. 208)

- …before fuel ever reaches the engine, it should pass through a remotely mounted primary filter. The primary filter prevents the most particle contaminants from ever reaching the secondary filter, and perhaps most important, it removes moisture from the fuel. Not only will water in the fuel deprive your expensive injection pump of essential lubrication, but if a drop let of water reaches the tip of an injected, the superheated air of cylindar will instantly convert it to steam, blowing the tip off like a tiny boiler explosion. The tip plays ping-ping inside the cylinder. On boy. (This Old Boat, p. 191)

- …prefilter the fuel going into your tank….for about $30 you can buy a fuel funnel with a screen that will pass diesel but not water…sailors taking on modest amounts of fuel should filter every gallon before it goes into the tank…because it is the stuff in the tank that clogs fuel filters and stops engines. (This Old Boat, p. 192)

Fuel Polishing – Methods

- The objective is to return and/or keep the fuel just like new. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- The basic concept of the depth type filter is that the fuel passes through a lot of filter media. For example, the fuel travels from one end of a roll of paper towels to the other as it passes through a GCF F-1 fuel filter thus the depth. It is that eleven plus-inches of contact with the filter media that makes this filter so efficient. It is its huge volume, when compared to the volume of a Racor-500 or 900 that gives it such an impressive capacity.Depth type filters are not required for the diesel polishing system, but they will increase the efficiency of the system and reduce the maintenance. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

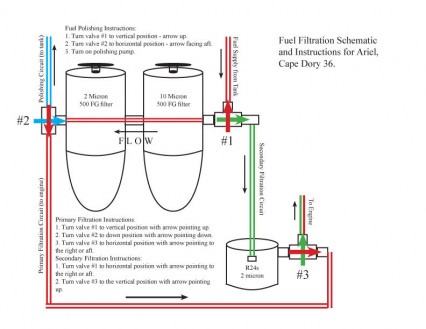

- I can use the fuel polishing pump to prime the system in a matter of seconds after filter changes, and I don’t have to worry about introducing air into the system….The Walbro pump has the capacity to turn over a tank of fuel in less than an hour….Here’s our filtration/polishing system.Two Racor 500 FG’s – 10 microns to 2 microns…Old R24s – lower right – is now part of a secondary filtration circuit to allow changing 500 FG filters while underway. The switch at left controls the Walbro fuel pump for polishing….only thing I’d like to add is a vacuum gauge to take the guesswork out of filter changes. My philosophy has always been “better safe than sorry,” but I’m not eager to change out perfectly good filters (http://www.capedory.org/board/)

- A dedicated polishing system with its own pickup way down in that sump to me, would be ideal…Inserting a dedicated pickup into that sump, connected to a high volume pump should clean the area where our hapless C. Resinae tends to collect, and in the long run, worth the trouble to install… LATER…If you have access and can install a fitting and pickup tube over the sump, I agree that that’s the way to go. (http://www.capedory.org/board/)

- How I dealt with the issue on my own vessel: #1 New tank #2 Permanently installed fuel polishing system from day one with its own supply & return tappings #3 Polishing system pick up 1/8″ from the absolute low spot in the tank #4 Polishing system runs when ever the engine runs and turns the tank over at a rate of 72 GPH #5 Polishing return is fed into a separate compartment and returned below the level of fuel to avoid foaming. #6 Racor 900 filter was used to accommodate capacity of 72GPH pump and to have more filter media. I spent only $96.00 more for this permanently installed always polishing system than the PO spend on a one time fuel polishing. The whole system cost me under $400.00….P.S. Fuel is still treated with a biocide, Startron and a cetane booster. (http://www.capedory.org/board/)

- strongly advised me to be very careful with any dissimilar metals finding their way into the tank. They also strongly advised against the use of any copper based alloys for fittings in direct contact with the tank, so I custom ordered all aluminum fittings. (http://www.capedory.org/board/)

- Pickup tubing – I have used PEX tubing before with good success. It is stiff enough yet also flexible enough and with enough feed back to feel your way along the bottom of a tank. If you cut the end at an angle you can often walk it along the bottom to the deepest corner then suck out the sump. If you need to pre-bend it a heat gun works well. (source)

- We then used a hand pump to remove fuel with large amounts of crud and water, let it settle a day, pumped again, let it settle, etc, for several days, until no more crud or water came out.Since then, we repeat this once a year, and get little or no more crud and no water. The bacteria require water, so we run all of our new fuel through a West Marine fuel filter that traps both particles and water. We try to keep our tank full to avoid any condensation. We installed a Racor filter that is much larger than that recommended for our engine, to provide extra filtering capacity. We also stopped using a biocide. (http://www.capedory.org/board/)

- All water should be drained from storage tanks periodically. The frequency will depend on the ease of removal, volume of fuel throughput and tolerance of water-related problems. It is not always an easy task, but tanks should never go more than 6 months without having bottoms removed.Be sure to remove water and bottoms until the product being removed is “clear and bright”. Remember, emulsions being held stable at the bottom of the tank due to sediment or biological growth can cause problems just as bad as if you were pumping straight water (http://www.cleanfuelguys.com/heat.html)

- Disadvantages – Fuel polishing won’t hurt anything but your wallet but, as I mentioned, won’t actually clean the tank, walls etc. something folks seem to think it will do. The problem with most tanks is that the pick up tube only goes within about 1 – 1 1/2″ to the bottom so you really never pick up the living debris accumulated on the bottom of the tank. (http://www.capedory.org/board/)

Fuel Polishing – Need For

- Very simple matter to measure the quantity of fuel returned to the tank. Just break into the return line to the tank and catch a known quantity of fuel in a known time and compute the flow rate. You can do this at the dock with the engine in neutral. Place a bucket under the return line and have a large zip-lock ready to catch the measured fuel. Have the engine started and increased the RPM to cruising speed. Then catch fuel in the zip-lock for a timed interval. The longer the timing interval the more accurate the results will be. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- It is generally agreed that water in the fuel tank causes all sorts of hell. The experts tell us that algae is born, lives, multiplies, and dies in the surface between the water and diesel fuel. These critters and their residue are a major source of trouble. The moral is: no water, no algae. Most of the water gets into our tanks by water condensing on the inside surface of the fuel tank and less often on the surface of the diesel fuel itself. This occurs every time the temperature of a surface is below the dew point temperature of the air to which it is exposed. Without getting too technical, more moist air will have a higher dew point temperature than less moist air and be more likely to cause condensation. It is also helpful to note that the condensation always occurs on the warm side of the surface (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- The most common means to prevent condensation in fuel tanks is to keep the tanks full. If they are full, there is no air in them so no condensation can occur. It is especially important to keep the tanks full when the boat is idle for a period of time. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- Desiccant filters in the vent lines have tremendous possibilities. If they can be fitted properly, they will keep most of the moisture in the air from entering the fuel tank, which will lower the dew point of the air to very low levels. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- It is one thing to get such dirt into a 20-gallon fuel tank and quite another to get it into a 300 or 400-gallon fuel tank on a trawler. The complete fuel turnover rate in the 20-gallon tank guarantees that the entire contents of the tank will be kept stirred up and the crud will quickly end up in our fuel filter. In the 400-gallon, on the other hand, the dirt will just settle to the bottom of the tank like the silt in the delta of a river. It will build there over time so that it can cause its worst evil at our most critical moment. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- Then there’s that black stuff that begins by discoloring the fuel filter, then discolors the fuel, then makes the fuel black and puts jelly-like stuff on the fuel filter, and then just shuts down the whole fuel system…I suspect it is the result of the solids from the original crude oil settling out and returning to their natural state. No matter what the cause, it is an ever-present, ever-continuing condition that adds to that awful mix at the bottom of our tanks. Let diesel fuel stand long enough and it will turn black. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- The common system with one secondary and one primary fuel filter tries to keep the fuel that enters the injection pump just like new and the only effect on the remaining fuel is the returned clean fuel. Once we understand that most of our engines return very little fuel to the tank it becomes obvious that this system has little or no effect on the fuel in our tank. The fuel in the tank keeps getting less and less just like new, and filter replacement intervals decrease. (http://www.trawlersandtrawlering.com/howto/captnwil.html)

- diesel fungus that was treated with a biocide. One of the most common is C. Resinae. The biocides tend to kill off the fungi or bacteria and then leave that residue behind which can plug a filter…the residue that gets on tank walls, and hides behind baffles, needs to be scrubbed clean or be given a chemical bath. I would strongly advise against the use of chains in tanks as even a small piece of dissimilar metal in the bottom of an aluminum tank can wreak havoc galvanically. (http://www.capedory.org/board/)

- There is, native to this planet, a life-form that thrives in diesel fuel. It’s commonly found in most tanks that aren’t really, really new. Ideally a biocide for treating diesel in a tank would kill and DISSOLVE the little critters. To my knowledge, none of them do…, so you just swap one problem for another. You have dead stuff that you must filter out, instead of live stuff that you must filter out. (http://www.capedory.org/board/)

- Upon inspection, when opening the top of the Racor filter, we saw there was not enough fuel in there… obviously, something went wrong along the fuel lines. Clogged, or crud from the tank, etc. A couple of days later, I cleaned up Racor as well as I could, replaced the filter which was absolutely full of junk, filled it up with new fuel. I also replaced the secondary fuel filter, cleaned the electric fuel pump. Then bled the system. My engine started again fine. However, since I have owned the boat-12 yrs. now, I have never cleaned that fuel tank… neither the PO. So I can only imagine what can be in there. I did not want to start my engine again without trying to do something about the fuel in that tank and trying to somehow clean it, if possible…Most of the water present in fuels will drop out as it is heavier than the fuel and will sink to the bottom if given time. (http://www.capedory.org/board/)

- Water gets into diesel fuel storage and vehicle tanks in several ways – by condensation of humid air, during transportation from refineries to service stations, by leakage through faulty fill pipes or vents and by careless handling. Water can cause injector nozzle and pump corrosion, microorganism growth and fuel filter plugging with materials resulting from the corrosion or microbial growth. Both vehicle and storage tanks should be checked frequently for water and drained or pumped out as necessary. In extreme cases, biocides may be required to control microorganism growth. In cold northern winters, ice formation in fuels containing water creates severe fuel line and filter plugging problems. Regularly removing the water is the most effective means of preventing this problem; however, small quantities of alcohol may be used on an emergency basis to prevent fuel line and filter freeze-ups. Cleanliness refers to the absence of water and particulate contamination. This characteristic is important because dirt and water can plug fuel filters in your engine and cause severe damage to your fuel injection system because of the close tolerances within fuel pumps and injectors. All diesel engine manufacturers equip their engines with fuel filters to protect the fuel delivery system. You should replace these filters according to the manufacturer’s recommendations. Some manufacturers also provide filters with drain valves and recommend periodic draining of any water that may accumulate from condensation and careless handling in storage or vehicle tanks. (http://www.cleanfuelguys.com/heat.html)

- Water in tanks can freeze 20F – 30F above the temperature at which fuel-related problems begin (cloud point). Ice crystals can build up on filters, restricting flow and compromising performance. They can also restrict fuel flow in tank pumping lines…In warmer weather, the presence of water in tanks may encourage the growth of fungi or bacteria which live in the tank water bottoms and feed on the fuel. Under the power of a microscope, these bugs look like deep-sea creatures. To the naked eye, these bugs show up as slimy mats of substance that can be any color from green to black. Under ideal conditions, these bacteria can double in number in as little as four hours. When left unchecked, they can be drawn out through suction lines and plug filters. In addition, the by-products of their fuel consumption are very acidic and can cause pitting and decay in tank bottoms. Many tanks go unchecked for years, accumulating water from any number of sources. (http://www.cleanfuelguys.com/heat.html)

- I think its a good idea to be able to have easy access to available fuel i.e.: you can easily pump it out to pre fill a filter or if someone is in need of fuel. Everyone I have talked to who have had to polish their fuel have had older boats (tanks) several owners, several levels of maintenance skills and a lot of crappy fuel from somewhere. So there is a lot of build up in those olds tanks. rough conditions stir it up and your filter is shot.I would carry a screen (Baja) to filter the fuel going into the tank if in doubt. And use the simplest way you can think of to be able to polish the fuel via an independent internal system while possibly still running the engine from the same tank.You will probably have a brand new or very cleaned out fuel tank to start with so you are way ahead already. I would check out the fuel treatment stuff if fuel sits for very long. (Ben Thomas, Beta Dealer)

Comment Form