Headliner

Image Gallery

Research

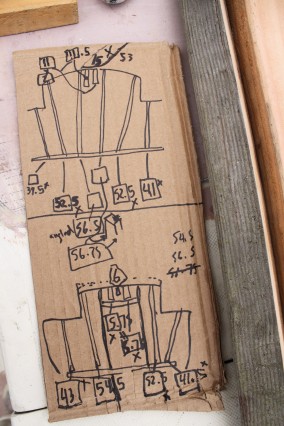

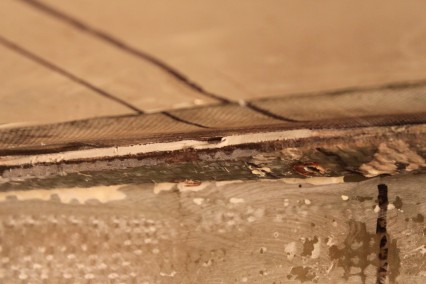

- To make ceiling strips, we usually rip 3/4-inch planks into 3-inch widths, then turn them on edge and re-saw them in half with a table saw or band saw. Done carefully with a jig, this results in two strips just less than 3/8 inch thick, each one with good planed side. For fancier installations, both sides can be planed, sanded, and sometimes matched for color and grain. Carefully fit the strip ends against bulkheads, or cut to a pleasing oval shape and rout the edges with a l/8-inch or l/4-inch bullnose. We attach the strips with flathead screws sunk flush or with screw caps. On large boats with thick ceiling strips, we plug the countersunk screw holes. (Upgrade Your Small Sailboat for Cruising)

Comment Form