Cockpit

Image Gallery

Project Logs

November 22, 2011

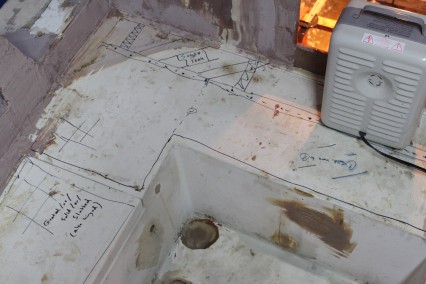

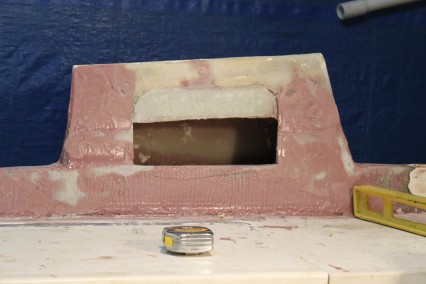

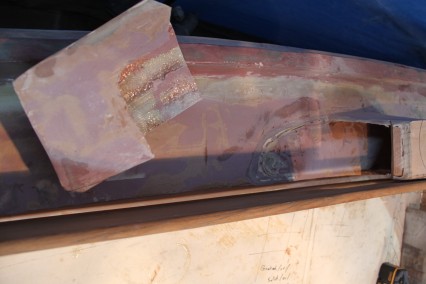

I applied my first layer of fairing on the majority of the cockpit last weekend. This meant the mattress supports, cockpit sole, hatch opening and traveler were all partly faired. I only partly faired them, because I still have more auxiliary cockpit construction to do before I can ready the entire area for paint. At this point though, major cockpit construction is complete and I’ll leave you with an image of the fairing as it looks today:

October 25, 2011

This past weekend I’ve completed construction of the cockpit sole. My process was as follows:

- Ground back the remaining bits of paint on the sides of the cockpit foot well to ready for final fiberglassing.

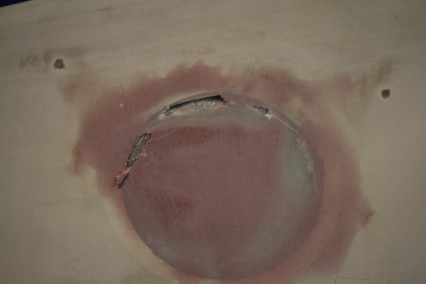

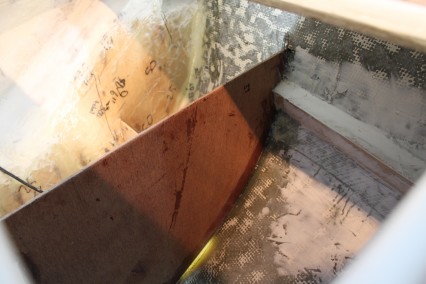

- Cut the final opening for the hatch and test fit the new Bomar aluminum hatch. I found that getting in and out of this hatch to access the area below the cockpit will be a tight fit (and perhaps not even possible). So I followed-up by cutting the access to the engine room which I will need to access the gear box once the engine is installed.

- Fiberglassed in the cockpit sole, as well as the sides of the hatch opening.

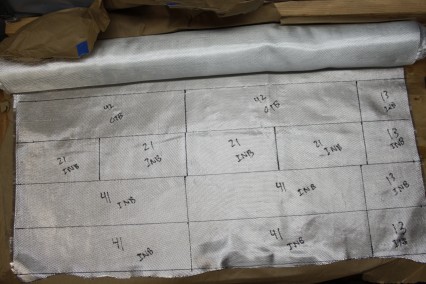

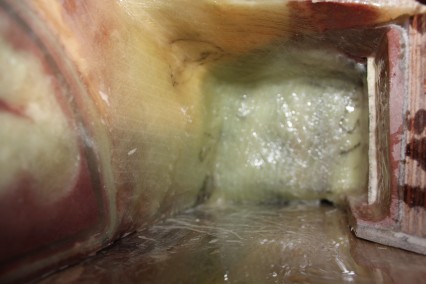

- Fiberglasses the backside of a bulkhead that supports the cockpit sole and forms the port sea locker. This bulkhead was installed months ago, however once I installed both the port and starboard bulkheads, I didn’t have access to this area and had to wait to cut a new opening below the cockpit to complete this final tabbing. As usual, I used 4″ and 6″ 1708 biaxial.

October 18, 2011

I’ve begun construction of the new cockpit. The reason I am modifying the cockpit sole so much is because I am modifying the drainage angle of the original cockpit sole so that water drains aft. The water will drain via the lazarette locker, through an aft chain locker and will exit via two drainage holes placed above the waterline in the transom of the boat. Here’s what I’ve completed so far:

- To begin this project, I first determined the location of the aluminum access hatch that I would be installing in the cockpit sole. Once I understood the location of the hatch, I cut through the cockpit sole to make room for the new access hatch. I was happy to see the thick fiberglass layup sandwiching a very dry balsa core. Once in place, the aluminum access hatch will allow me to enter the area below the cockpit which houses the prop shaft stuffing box as well as the rudder stuffing box.

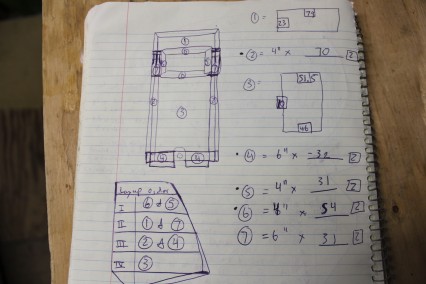

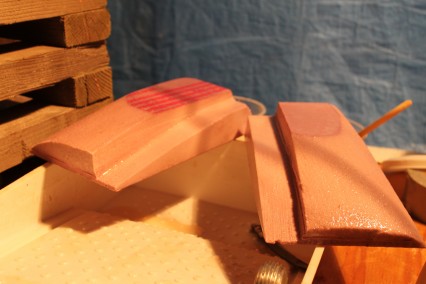

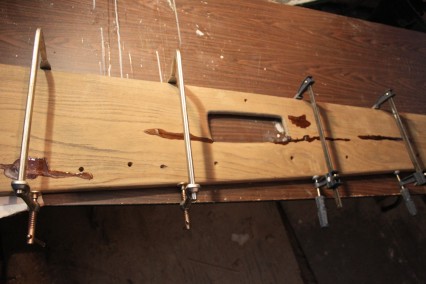

- With the hatch location understood, I began to frame out the new cockpit sole using oak frames. I built the sides of the hatch opening out of 1/2″ marine plywood and then epoxied and fiberglassed the oak frames in place. Though this was likely overkill to fiberglass them in place as well, that’s been the story for the entire boat so far – build things very strong!

- Once the frames were in place, I used pour foam to fill the voids between the supports. I could have first installed the sole, drilled holes in the sole, and poured the foam into these holes, however I was a little concerned that that might result in voids below the sole that I wouldn’t be able to account for due to the low temperatures of the night of installation, I decided to pour the foam first, then carve the foam to shape using one of my favorite tools – a sawzall. I like using pour foam not only for filling inaccessible voids, but I also appreciate the benefit of adding extra flotation.

- I then templated, cut and fit the new cockpit sole from 1/2″ Meranti marine plywood. I also cut and prepared Baltek fiberglass strips which would be placed on top of the oak frames and would bond the Meranti cockpit sole to the frames.

Before long, I will grind back more paint from the sides of the cockpit sole and fiberglass the sole in place permanently.

Research

- …key considerations…is the height of the sole and seat. If either is too low, the crew will have to work to get their jobs done; if too high, they will not feel protected. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 123)

- There are three limits on the height of the cockpit sole: 1) it must be located high enough above the waterline so that the cockpit will drain automatically when the boat is either level or heeling at an extreme angle. 2) Must be high enough to permit the helmsman to see over the cabin trunk, preferably from a sitting position and definitely from a standing one 3) Should not be so high that it raises the seats to the level of the deck. The reason seat height is so important is that, when the seats are elevated above the level of the deck, people sitting on them will feel like they are perched insecurely on the deck rather that sitting safely in the cockpit. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 123)

- Since the height of seats above the cockpit sole – ideally 15 to 18 inches – is determined by the dimensions of the human body and therefore cannot be radically altered, the height of the cockpit sole determines the height of the seats….The feeling of security in this kind of cockpit seat is enhanced if the backrests are 12 to 15 inches high. The angle of the seat back should be such that a sitter is not pushed off the seat when the boat heels or rolls. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 124)

- Some other key dimensions work in most cockpits….The seats should be 18 – 20” in width and at least 6’ 6” in length…if the seats are parallel to each other and 24 – 30” apart, a person sitting on the windward seat can comfortable brace [their[ feet against the leeward seat when the boat is heeled. Ideally, the cockpit should be sunken enough so that, when inserted in the winches, the distance from the cockpit sole to the tops of the winch handles should be about 42 inches, which is the most efficient working height for a winch-grinder. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 124)

- The sole and seats should be surfaced with teak or some other suitable non-ski surface. It’s a mistake to use long, thick cockpit cushions…that can catch feet and turn ankles…save the soft ones for port. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 124)

- A backrest nicely angled (about 15 degrees) is essential for comfort as well as safety, for then one can brace oneself with little effort. (From a Bare Hull, p. 36)

- Backrests can be moved inboard more easily than outboard. False backrests can be fashioned…Most people are most comfortable and least tired if their legs can extend straight to the footrest so that leg muscles don’t need to be flexed. Sitting for long periods with knees bent is very tiring. (Upgrading the Cruising Sailboat, p. 177)

- If you’re going to spend 50% of your time in the cockpit, it really should have a comfortable length and width – at least enough to lie down in. (Upgrading the Cruising Sailboat, p. 177)

- The lower limit on length should be determined by the need to have the seats long enough for someone to sleep on them (i.e., something more than 6’ or 1.8m). The seats need to be straight for at least 6’ and as parallel to the centerline as possible (so that one end is not higher than the other when the boat is heeled). To make comfortable berths, the seats need to be 20’ – 24’ (50 – 60 cm) wide. Cockpit width is determined by the need to be able to sit on one seat and comfortably brace your feet on the opposite seat when the boat is well heeled. In practice 24’ (60cm) is ideal, 30’ (76cm) very much the upper limit… (Cruising Handbook, p. 77 – 8 )

- To be comfortable, seats need to be 15’ – 18’ above the cockpit sole (including the depth of any cushions), and with seat backs 15 – 20” high, angled outboard by 10 – 15 degrees. Ideally, the aft end of the main cabin will also be sufficiently raked to form a comfortable backrest (it rarely is). The cockpit combings should meet the cabin at right angles, enabling someone to get comfortably wedged in place when stretched out on the seat facing aft. Too often, designers round the corners on modern cockpits. Regardless of how aesthetically pleasing this may be, it is not comfortable! (Cruising Handbook, p. 78)

- Given that very little watchkeeping is done from behind the wheel or holding the tiller, there needs to be a secure, comfortable location for the watchkeeper, protected from the elements, but still with good all-around visibility. This is not so easy to achieve, especially once a dinghy and maybe a life raft are stowed on deck. Visibility is commonly compromised. (Cruising Handbook, p. 81)

- Seats should be designed to drain at up to a 30-degree angle of heel. (Cruising Handbook, p. 92)

- Can you sleep on the seats? This may be very important for night watches during long passages. (You may want to sleep there while your mate is at the wheel. Are the seats comfortable? Is the back high enough? Is the incline comfortable? (All in the Same Boat, p. 45 – 5)

- There should be no interference between the sweep of the tiller and the working of a winch. People should be able to reach seats, cleats, and winches without having to stumble all over the cockpit. The coamings should be high enough to keep out green water, low enough for comfortable sitting with elbows over their upper edges, and sloped outward for sitting comfort. The binnacle should be strong enough to support somebody lurching heavily in rough weather. The cockpit seats should be well thought out….As a rule, the inboard edges of seats should be parallel to each other, a leg span apart….You should be able to open and close the cockpit lockers without moving all the lines out of the way. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 113)

- The cockpit should be designed around the steering gear (Desirable and Undesirable Characteristics of Offshore Yachts, p. 122)

- …construction scantlings should match those of the main deck. Two types of structural stiffening are needed. One is the stiffening or support needed to carry the weight of the cockpit and its contents – its equipment, the crew, and any load of water that may decide to come along….This support is best provided by fitting longitudinal bulkheads at each side of the cockpit well or transverse bulkheads at each end. Each of these bulkheads should extend below the cockpit and be attaches to the boat’s floors. The other type of stiffening required is the way of the winches…doubling of all materials is usually required so that the deck or cockpit sole will not deflect from the large horizontal loads that are applied to this gear. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 123)

- Along with the berths, the cockpit is the most used locale on a sailboat. Let’s list some [requirements of a good cockpit design]: 1) Comfortable seating, level or heeled 2) Small volume, to minimize amount of water that could fill it 3) Large scuppers 4) Good visibility over the cabin 5) Surfaces to brace feet when heeled 6) Easy to handle sheets and lines 7) Convenient access to lockers and/or lazarettes 8 ) Bridge deck or high companionway sill 9) Long enough to lie down (Upgrading the Cruising Sailboat, p. 176)

- A fully enclosed cockpit adds a considerable living area to the boat (Cruising Handbook p. 87)

- The basic theme, as repeated over and over in this book, is comfort safety and utility. The stipulation of comfort is more than hedonism. An exhausted crew is a crew capable of placing the entire vessel in danger; a rested crew is stronger and makes better decisions. Utility concerns the the ability o efficiently carry out the multifarious functions necessary to keeping the ship going each day. The ease with which one can handle lines, find the jerry jug in the cockpit locker, toss a life ring to someone overboard, trim the mainsheet or lie down for a snooze are all factors to consider… (Upgrading the Cruising Sailboat, p. 176)

- Above all else, a cockpit has to create a secure, comfortable working space at sea…. (Cruising Handbook, p. 77)

- The cockpit sole must clearly be high enough for an average person standing at the wheel, sitting on the helmsperson’s seat, or operating a tiller to have a clear line-of-sight forward, but also low enough to provide a clear view of the sails. (Cruising Handbook, p. 80)

- We believe seats should be about 17″ or 18″ from the sole and about 17″ to 20″ wide. The wider seat dimension would accommodate backrest cushions and sleeping…Seat cushions are largely a matter of preference, the potential for added comfort must be weighed against their effect on seat geometry and difficulty in stowage when not in use. They may also require fiddles to keep them in place, making sitting uncomfortable when the cushions are not in use…Seat cushions are largely a matter of preference, the potential for added comfort must be weighed against their effect on seat geometry and difficulty in stowage when not in use. They may also require fiddles to keep them in place, making sitting uncomfortable when the cushions are not in use. Perhaps the best argument for the use of cushions is shock and vibration. When you initially sit down, or as the boat falls off a wave, the shock compresses the discs in your back, leading to strain in your lower back.Long periods of time are also often spent motoring or with a generator operating; vibration-sensitive people can become ill as a result of vibration.For maximum long-term comfort, seat cushions need not be more than about 2″ thick. Construction should be comprised of 1-1/2″ medium foam padding glued on top of 1/2″ firm, closed-cell foam. Seat covering material should not be coarse or slippery, but should breathe, resist mildew and have UV protection. Marine acrylics do a good job.As for color, a non-reflective light gray is the best choice for cushion coverings, for the same reasons light gray non-skid is popular (i.e., it has low reflectance, stays relatively cool and is psychologically neutral). If you find gray too boring, a neutral green or blue green is also a good choice. Green, not only low in reflectance, has been found to have a calming psychological effect (http://www.practical-sailor.com/marine/sailboat-cockpit-seating.html)

Bridgedeck

- A valuable structural member is a bridge deck between the cockpit and the companionway. The bridge deck helps to hold the port and starboard sides apart while absorbing athwartship stresses….Another advantage of the bridge deck is that it is a strong, simple support for the main sheet traveler. If the traveler is put on the cabin roof, it will require complicated supports. (Desirable and Undesirable Characteristics of Offshore Yachts, p. 106)

- …it also helps to keep the ocean out of the cabin after a breaking wave fills the cockpit. Another important barrier is a set of strong boards to be inserted in the companionway, which should be capable of being secured with a lock so they won’t fall out in a very bad roll. (Desirable and Undesirable Characteristics of Offshore Yachts)

- A bridge deck is a desirable feature in any cockpit. In addition to contributing to overall strength of the vessel, it reduces cockpit volume, helps to raise the companionway still to a safe level, and adds extra usable space in the cabin underneath. This is a good place for a main sheet traveler, not only because the deck is strong, but also because, when the boat is on the wind, it allows the main sheet to function as a stanchion-like hand hold for people emerging from the companionway (Desirable and Undesirable Characteristics of Offshore Yachts, p. 122 – 3)

- I have a strong dislike of bridge-deck-mounted mainsheet travelers. At best, they always seem to be in the way; at worst, they are a distinct hazard… (Cruising Handbook, p. 91)

- The farther offshore a boat is intended to sail, the greater the importance of having a bridge deck between the cockpit well and the companionway hatch. (Cruising Handbook, p. 91)

Coamings

- …they [European Yacht designers] angle the top half of the coaming outboard more than the bottom half, and round the top edge. The coaming is thus shaped to fit the curvature of a back, with no hard spot at the top….A high cockpit with coaming of a decent height raises the coamings a considerable way off the deck, making it difficult to enter and exit the cockpit. Some kind of step or lowered section of coaming (or both) is needed. Another factor to be considered relative to high cockpits – with or without decent coamings – is safety in rough weather or when moving in and out of the cockpit. If the boat makes a sudden lurch at the wrong moment, there is a much greater likelihood of being pitched clear over the lifelines than with a more traditional cockpit. (Cruising Handbook, p. 78)

- There needs to be an adequate number of handholds and harness-attachment points. (Cruising Handbook, p. 78)

- If a cockpit has the kind of seat-back depth recommended (15″ – 20″) and if the coaming are wide enough (12″), they become comfortable seats themselves. This is an excellent watchkeeping location in fair weather…There is a good line-of-sight up the side deck and a view of the set of sails. (Cruising Handbook, p. 78)

- Coamings should incorporate coaming boxes for stowage of halyards, sheets, binoculars, gloves, winch handles, suntan oil, and all the other miscellanea that invariably end up in the cockpit. (Cruising Handbook, p. 78)

- The primary winches are almost always on the coamings. It just so happens that the optimum height for a winch handle to be above the cockpit sole is 40 – 45″, which fits rather nicely the optimum dimensions already outlined (seats 15 – 18″ off the sole, coamings 15 – 20″, and the winch and its handle adding another 10″). The coamings almost always need to be angled outboard to provide a fairlead for the headsail sheets up onto the winches. Winches need to be located such that they are both comfortable to work and accessible from the watch keeping station so that lines can be rapidly cast off when necessary. (Cruising Handbook, p. 78)

Comment Form